Author: Site Editor Publish Time: 15-12-2025 Origin: Site

In North America, stretch film is no longer a "low-tech consumable."

For US buyers, it directly impacts transportation safety, labor efficiency, warehousing costs, customer claim rates, and ESG compliance risks.

Stretch film is an irreplaceable basic material, especially in the following scenarios:

Third-party warehousing (3PL)

E-commerce fulfillment centers (Amazon/Walmart/Shopify)

Food and beverage delivery

Building materials, chemicals, daily necessities, and FMCG transportation

However, the reality is that many US buyers are both dependent on and dissatisfied with stretch film.

Raw material LLDPE (especially C4/C6/C8) prices are significantly affected by crude oil prices, US resin plant maintenance, and import tariffs.

Buyers often ask:

"Why is the same gauge film $10–20 higher than last quarter?"

We break down the price as follows:

Resin cost (LLDPE C4/C6/C8)

Gauge/Micron

Yield (lbs per roll)

Pricing is adjusted based on the current resin market, not arbitrary markup.

Many suppliers claim 200%/250%/300% stretch, but in reality, this is impossible to achieve by hand wrapping or semi-automatic machines in the warehouse. These are parameters based on real-world usage scenarios, not laboratory data.

We provide:

Hand wrap: real stretch 80–120%

Semi-auto: 150–200%

Auto machine: 220–250%

We will first understand three questions:

· Machine brand & model

· Load weight & shape

· Target stretch %

We will then provide specific recommendations for different equipment.

In the United States, shipping claims are a very real cost issue.

Buyers' biggest fears:

Pallets shifting during long-haul truck transport

Pallets collapsing during transshipment

Customers refusing delivery or demanding compensation

In the North American market, stretch film is not only a packaging material but also a key variable in logistics security and cost control.

Many American buyers, when purchasing stretch film, often only focus on the price per roll, neglecting the following realities:

Long transportation distances (interstate/international)

High levels of warehouse automation (requiring higher film performance)

High labor costs (operational efficiency directly impacts costs)

Clear liability for damage (packaging issues = direct compensation)

The result is:

"Buying cheap, but using more expensive."

1. Choose according to the usage method: manual or machine use.

| Usage Method | Key Indicators | Recommended Solution |

| Hand Stretch Film | Easy to stretch, good feel | medium stretch ratio, stable adhesion |

| Machine Stretch Film | High stretch ratio, strong retraction | pre-stretched, high strength |

2. Select membrane structure based on cargo weight.

| Cargo Weight | Recommended Membrane Type |

| Lightweight (<500kg) | Standard LLDPE |

| Medium (500–1000kg) | Reinforced Stretch Membrane |

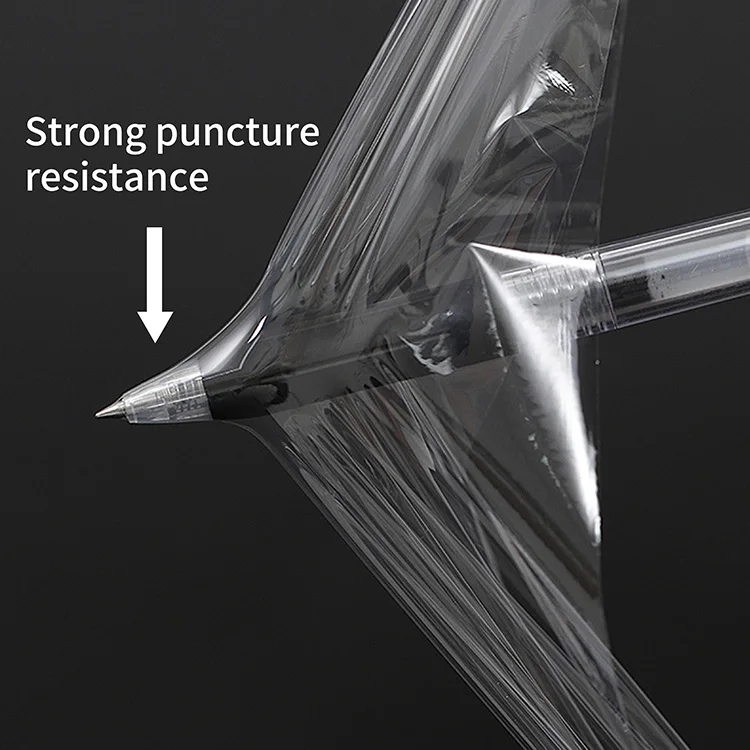

| Heavyweight (>1000kg) | High Puncture Resistance, Nano Stretch Membrane |

3.Focus on elongation, not just thickness.

| Parameter | Their True Meaning |

| Thickness (Gauge) | Original material thickness |

| Elongation | Actual material savings |

| Retraction Force | Pallet stabilization capability |

In the North American market, stretch film has never been a "low-tech product."

A truly professional choice should consider:

Usage scenario

Cargo structure

Logistics environment

Labor and equipment

Long-term total cost

Choosing the right stretch film is not just about saving materials, but also about:

Reducing cargo damage

Improving efficiency

Lowering overall logistics costs

Please provide your pallet weight, wrapping method, and warehouse conditions—our team will recommend a customized stretch film solution to reduce costs and improve cargo stability.