Author: Site Editor Publish Time: 22-12-2025 Origin: Site

Hand Stretch Film vs. Machine Stretch Film

Choosing the Right Stretch Wrap for Your Application

Stretch film plays a critical role in modern logistics, warehousing, and transportation. Choosing the right type of stretch film not only affects load stability, but also directly impacts labor efficiency, material cost, and overall operational performance. The two most common options are hand stretch film and machine stretch film—each designed for different applications and usage environments.

Understanding the differences between these two types will help businesses optimize pallet wrapping, reduce waste, and improve shipping safety.

What Is Hand Stretch Film?

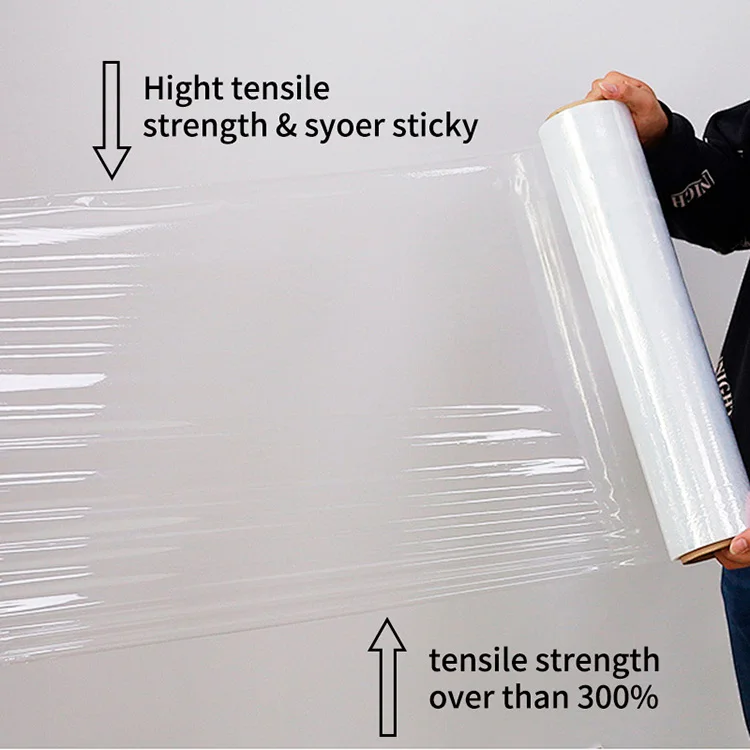

Hand stretch film is designed for manual application and is typically used in low- to medium-volume operations. It is applied by hand, often with the help of a dispenser, making it ideal for small warehouses, retail backrooms, or operations without automated wrapping equipment.

Hand stretch film is known for its flexibility and ease of use. It allows operators to wrap pallets of various shapes and sizes without complex setup or machinery. This makes it a practical choice for businesses with limited daily pallet output or frequent changes in load configuration.

Easy to apply without equipment

Strong load containment and stability

Lightweight rolls reduce operator fatigue

Ideal for warehouses, retail backrooms, and small logistics hubs

Our hand wrap is manufactured using high-quality LLDPE materials, offering superior puncture resistance and reliable stretch for daily shipping needs.

Machine stretch film is engineered specifically for automated or semi-automated pallet wrapping machines. It is commonly used in high-volume distribution centers, manufacturing plants, and logistics hubs where speed, consistency, and load security are essential.

Machine stretch film is designed to stretch at higher ratios, delivering stronger load containment with less material. When used with the proper wrapping equipment, it ensures uniform tension, improved pallet stability, and reduced film waste.

Designed for automatic and semi-automatic wrappers

Higher stretch capability for reduced film consumption

Consistent tension and wrapping quality

Ideal for distribution centers and manufacturing facilities

By using machine-grade stretch film, businesses can improve packaging speed, reduce material waste, and achieve long-term cost savings.

Hand Stretch Film vs. Machine Stretch Film

| Feature | Hand Stretch Film | Machine Stretch Film |

|---|---|---|

| Application | Manual | Automated / Machine |

| Ideal Volume | Low to medium | Medium to high |

| Stretch Capability | Lower | Higher |

| Consistency | Operator-dependent | Highly consistent |

| Labor Requirement | Higher | Lower |

| Material Efficiency | Moderate | High |

Choosing the right stretch film depends on your packaging volume, workflow, and equipment setup.

Both our hand and machine stretch films are available in:

Clear or colored film

Standard or high-performance grades

Recyclable and downgauged options

Custom thickness and roll sizes

Each roll is precision-wound to ensure smooth unwinding, consistent cling, and dependable load security.

The choice between hand and machine stretch film depends on several factors, including daily pallet volume, load weight, warehouse workflow, and budget considerations.

If your operation wraps a small number of pallets per day and values flexibility, hand stretch film is a cost-effective and practical solution.

If you operate a high-volume facility where speed, safety, and efficiency are critical, machine stretch film offers superior performance and long-term savings.

Many growing businesses start with hand stretch film and transition to machine stretch film as their logistics operations scale.

Professional stretch film manufacturer with export experience

Stable quality and consistent roll performance

Custom specifications available

Competitive pricing for wholesale orders

Support for North American logistics standards

At M-Star Packaging, we manufacture both hand and machine stretch film using high-quality LLDPE materials to ensure strength, clarity, and consistent performance. Our stretch films are designed to improve load stability, reduce breakage, and optimize wrapping efficiency across a wide range of industries.

Whether you need manual stretch wrap for warehouse flexibility or machine-grade film for automated systems, our team can help you select the right solution based on your specific application requirements.

Whether you need flexible hand stretch film for daily warehouse use or high-efficiency machine stretch film for automated lines, M-Star Packaging is ready to support your business.

Contact us today to discuss your application and receive a customized stretch film recommendation.