Author: Site Editor Publish Time: 13-02-2026 Origin: Site

The rise of the pre-prepared food industry has driven advancements in food packaging technology. Retort pouches (retort bags) are specially designed to withstand high-temperature processing, typically between 121°C and 135°C, maintaining shelf stability without refrigeration.

Retort bags are rarely made from a single material. They are complex multi-layered composite materials, each layer having a specific function.

Common Composite Material Structures

BOPA/RCPP: High transparency, suitable for short shelf lives.

PET/AL/RCPP: The gold standard. Offers the highest light and oxygen barrier properties.

PET/PA/AL/RCPP: Four-layer structure, providing maximum puncture resistance and durability.

Layer Structure Breakdown

Outer Layer (PET - Polyethylene Terephthalate): Provides heat resistance, structural integrity, and a high-quality printable surface.

Intermediate Layer (BOPA/Nylon): Offers excellent puncture resistance and flexibility, preventing pinhole damage during transport.

Barrier Layer (AL - Aluminum Foil): Barriers against oxygen, moisture, and light. In "transparent" retort pouches, this layer is replaced by an alumina (AlOx) or silica (SiOx) coated film.

Inner Layer (RCPP - Retortable Cast Polypropylene): A heat-sealing layer. Must remain stable and meet food safety standards at temperatures exceeding 121°C.

To ensure the safety of pre-prepared foods, materials must meet stringent physical performance standards:

Even the best materials can fail if handled improperly. Users must pay attention to the following:

A. "Cold Spot" and Heat Distribution

During retort cooking, ensure heat reaches the center of the food packaging. Over-stacking packaging bags in an autoclave can cause a "cold spot," allowing bacteria (such as Clostridium botulinum) to survive.

B. Pressure Compensation (Back Pressure)

As temperature rises, the air and moisture inside the packaging expand. To prevent the packaging from bursting, the high-temperature, high-pressure sterilization equipment must apply external air pressure to counteract the internal pressure.

C. Cooling Stage

Rapid cooling after cooking is crucial for maintaining the texture of food, but care must be taken to avoid "thermal shock," as it weakens the adhesive strength of the composite material.

D. Avoid Sharp Objects

Although the BOPA layer is puncture-resistant, bone-in meats (such as pork ribs) may still puncture the inner RCPP layer during high-pressure cooking. It is recommended to use a dedicated "bone-protecting" film for such products.

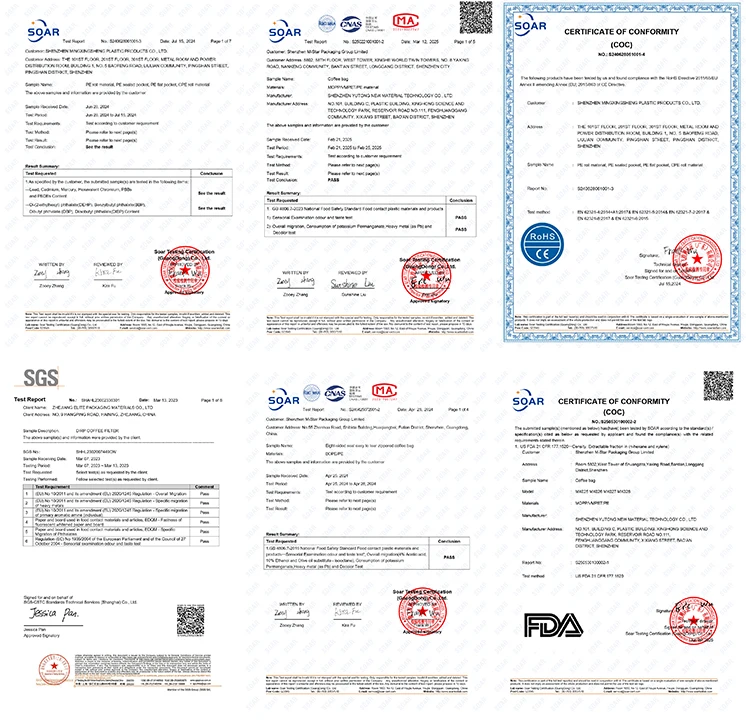

Exporting or selling pre-prepared foods requires packaging that complies with stringent international food contact materials (FCM) regulations.

Global Standards

US Food and Drug Administration (FDA): Complies with the provisions of 21 CFR 177.1500 and 177.1390 regarding high-temperature composite materials.

EU Regulation (EC) No 1935/2004: Framework for all food contact materials.

GB 4806.1 (China): National safety standard for food contact materials and articles.

Required Certificates for Manufacturers

ISO 9001 and ISO 22000: Quality and food safety management systems.

BRCGS (Global Packaging Materials Standard): Typically required by European retailers.

Migration Test Report: A certificate proving that heavy metals and phthalates do not migrate into food at temperatures above 121°C.

SGS/Intertek Laboratory Report: Used for compliance with specific chemicals (RoHS, REACH).

onclusion:High-temperature retort packaging is a mainstay of the modern pre-prepared food industry. Success depends on the synergy between materials science (selecting the appropriate PET/AL/PA/CPP ratio) and process control (controlling pressure and temperature).

To ensure food safety and packaging integrity, you must strictly adhere to the following five core points during retort processing:

1. Pressure Balance (Back Pressure Control)

This is the most crucial point.

Principle: During heating, moisture inside the packaging bag turns into steam, causing air to expand and resulting in a significant increase in internal pressure. If the pressure inside the autoclave is lower than the pressure inside the bag, the packaging will burst like a balloon.

Operation: A back pressure autoclave must be used. During the heating and cooling phases, compressed air is injected into the autoclave to make the pressure inside slightly higher (usually 0.02-0.05 MPa higher) than the pressure inside the bag, thus counteracting the internal expansion.

2. Air Removal

Risk: If too much residual air is left in the packaging bag during sealing, the coefficient of air expansion during heating is much greater than that of liquid, easily causing rupture.

Recommendation: Maximize the vacuum level as much as possible before sealing. For pre-cooked dishes with broth, use "heat filling" or vacuum sealing to reduce the amount of residual air.

3. Heating and Cooling Rate Control

Preventing Thermal Shock: Excessive heating can cause a large temperature difference between the inside and outside of the bag, affecting the adhesive strength of the composite film.

Critical Cooling: The cooling phase after sterilization is a high-risk period for bag breakage. Cooling water must be introduced while maintaining pressure inside the sterilizer. If pressure is released directly before cooling, the bag will burst instantly due to the excessive pressure difference.

4. Stacking and Flow Distribution

No Stacking: Bags should not be stacked too densely in the sterilization basket. If bags are crowded together, heat cannot penetrate to the "cold spot," leading to incomplete sterilization. Additionally, compression can easily create wrinkles, and pressure at high temperatures can cause the heat seal layer to thin.

Using Dividers: It is recommended to use perforated stainless steel dividers to ensure that hot water or steam flows evenly over the surface of each bag.

5. Material Matching and Residual Heat Check

Upper Temperature Limit: Confirm whether your packaging bags are rated for 121°C or 135°C. It is strictly forbidden to use ordinary retort pouches (121°C) for high-temperature sterilization at 135°C. Otherwise, the adhesive will degrade, causing delamination and even unpleasant odors.

Sealing Inspection: After cooking, randomly check the seal strength of the bags. High temperatures will soften the RCPP (inner film), and if there are oil stains or sauce contamination at the seal, it is very easy for the seal to slowly leak under high temperatures.